LOCATION:

Gwynedd, Wales

SECTOR:

Personal Protective Equipment

PRODUCT:

1128 Bluetooth® UHF RFID Reader

DMM Revolutionises PPE Safety Management by Integrating RFID Technology Into Digital Inspection and Inventory

Project Overview

DMM specialise in providing tracking solutions for Personal Protective Equipment (PPE) such as ropes, harnesses and slings, which are traditionally difficult to mark and track due to the extreme environments and physical handling they are subjected to.

Challenge

To design a solution that improves identification & inspections of safety equipment, avoiding the pitfalls of the traditional manual methods:

- Accuracy – Laser etched serial numbers require human reading. Manually typing serial numbers is very slow and mistakes can be made.

- Slow to reference accurate product information and associated documentation.

- Time consuming – the longer safety management and inventory takes, the more it costs.

- Durability – current laser etched identification can become difficult or impossible to read. This reduces the product’s lifespan and adds expense.

Solution

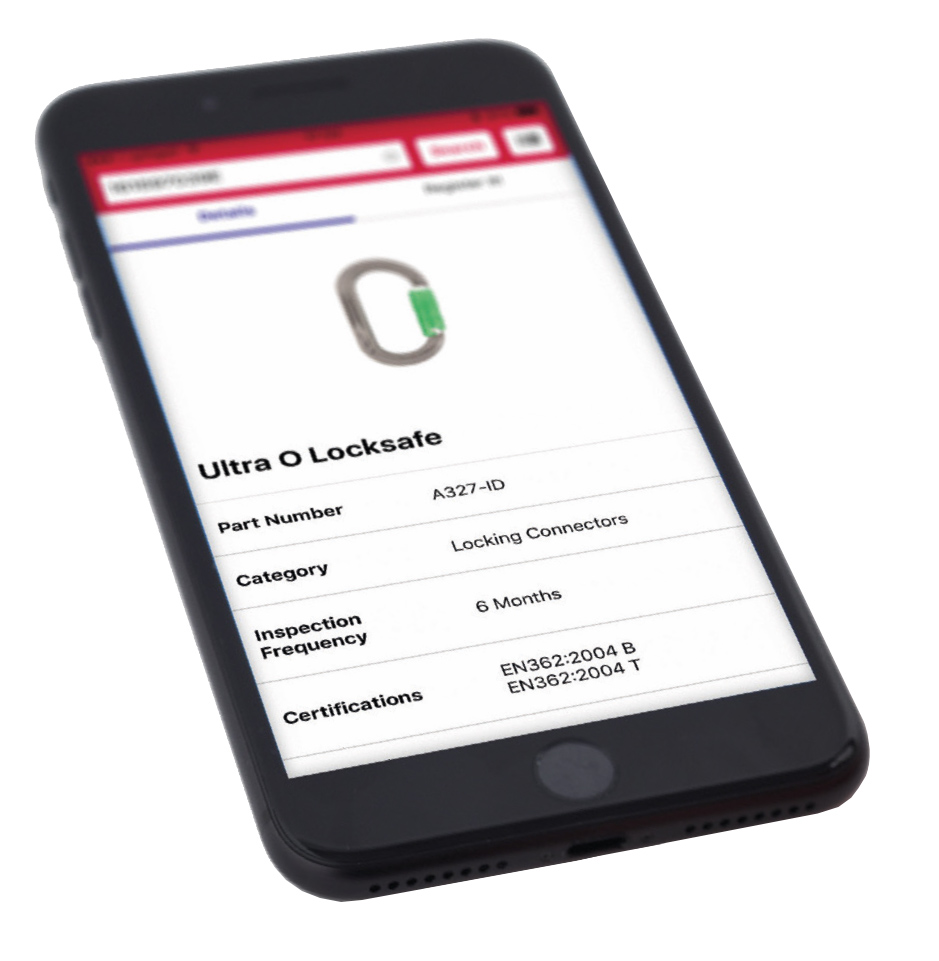

DMM iD 2.0 is a new addition for 2020, expanding on DMM’s exisiting asset management solution by incorporating the TSL® 1128 Bluetooth® UHF RFID Reader, adding the ability to read multiple items at the same time, and at long distances.

TSL® 1128 Bluetooth® UHF RFID Reader with one of the many optional slide-on smartphone mounts available

The UHF RFID Reader connects to any Bluetooth® host device – e.g. a smartphone running a custom app – and works like a keyboard, entering serials into any field.

DMM started with ‘read on contact’ technology, due to the challenges of reading RFID tags ‘on or in-metal’ items, but added UHF RFID so that multiple items could be scanned at distance. This is currently possible using UHF RFID tags, which are built into their Centre Harness range, sewn rope terms, Coron Helmet and Retrofit Rope Label & Helmet iD tags. The smaller metal Connectors are grouped into kitbags, and the kitbag iD Tag can be scanned at a distance by the TSL® 1128 Bluetooth® UHF RFID Reader .

The scanned product data can be recorded in .CSV format, Excel or imported directly into Papertrail, a cloud-hosted inspection management service.

Result

DMM iD 2.0 reduces human error, improves accuracy and accountability and saves time and money.

Customers can manage their entire stock with one RFID system.

The unique serial number of iD enabled equipment is automatically typed into the device upon being scanned. This reduces time compared to manually reading and typing-in the serial number.

Because iD enabled products effectively have indelible serial numbers, they can continue to be inspected and used after the laser markings have worn off. Products no longer need to be retired once the serial numbers have become unreadable, removing the cost of replacing them prematurely.

Scanning the product’s iD tag removes human error associated with manual data entry and typing the serial number; increasing the accuracy of inspection records.

About

DMM are based in Gwynedd, Wales.

For more information on their products and services, visit them at dmmwales.com/id or email iD@dmmwales.com